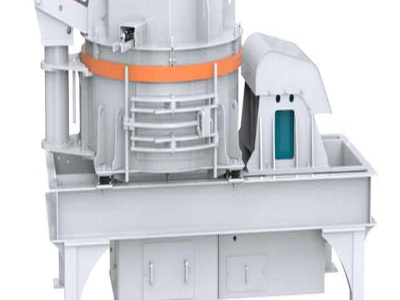

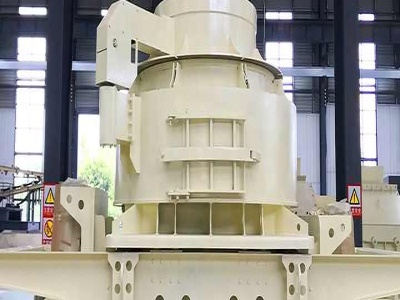

Power Mills | Mill Technology | GE Steam Power

Licenses for our milling technology can be found in all coalpowered regions of the world. Pulverizing solid fuel to powder enables its drying and transport for combustion in large furnace sizes. Fine grinding increases the fuel exposed surface area while simultaneously drying and controlling its distribution.